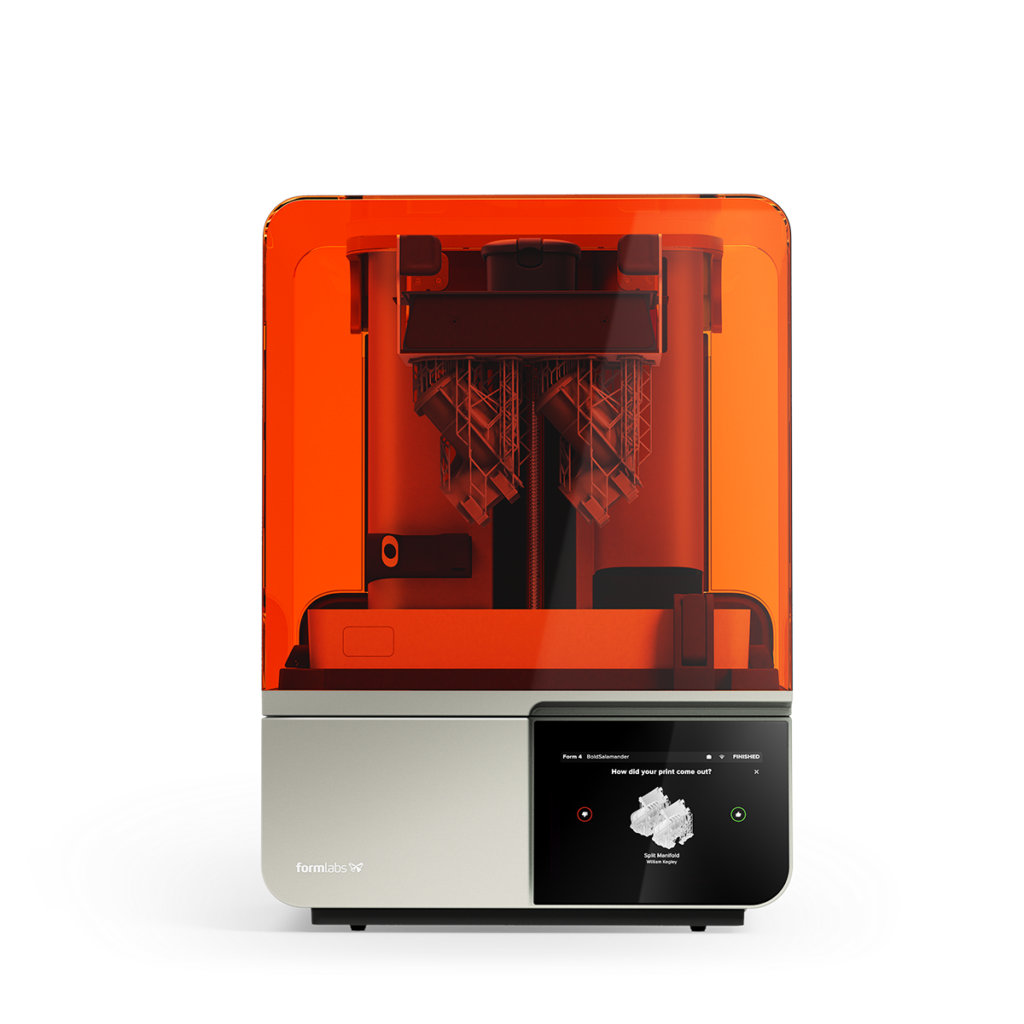

Form 4

Combining High Speed with Industrial Production

Accomplish more with most prints completed in less than 2 hours.

Game Controller

Consumer Products

Lightbar & Mount LED

Automotive

Robotic Finger

Robotics

Connector

Electronics

Create impeccable parts that consistently match or exceed the quality of injection-molded components.

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

±0.15% XY dimensional tolerances so assemblies always fit.

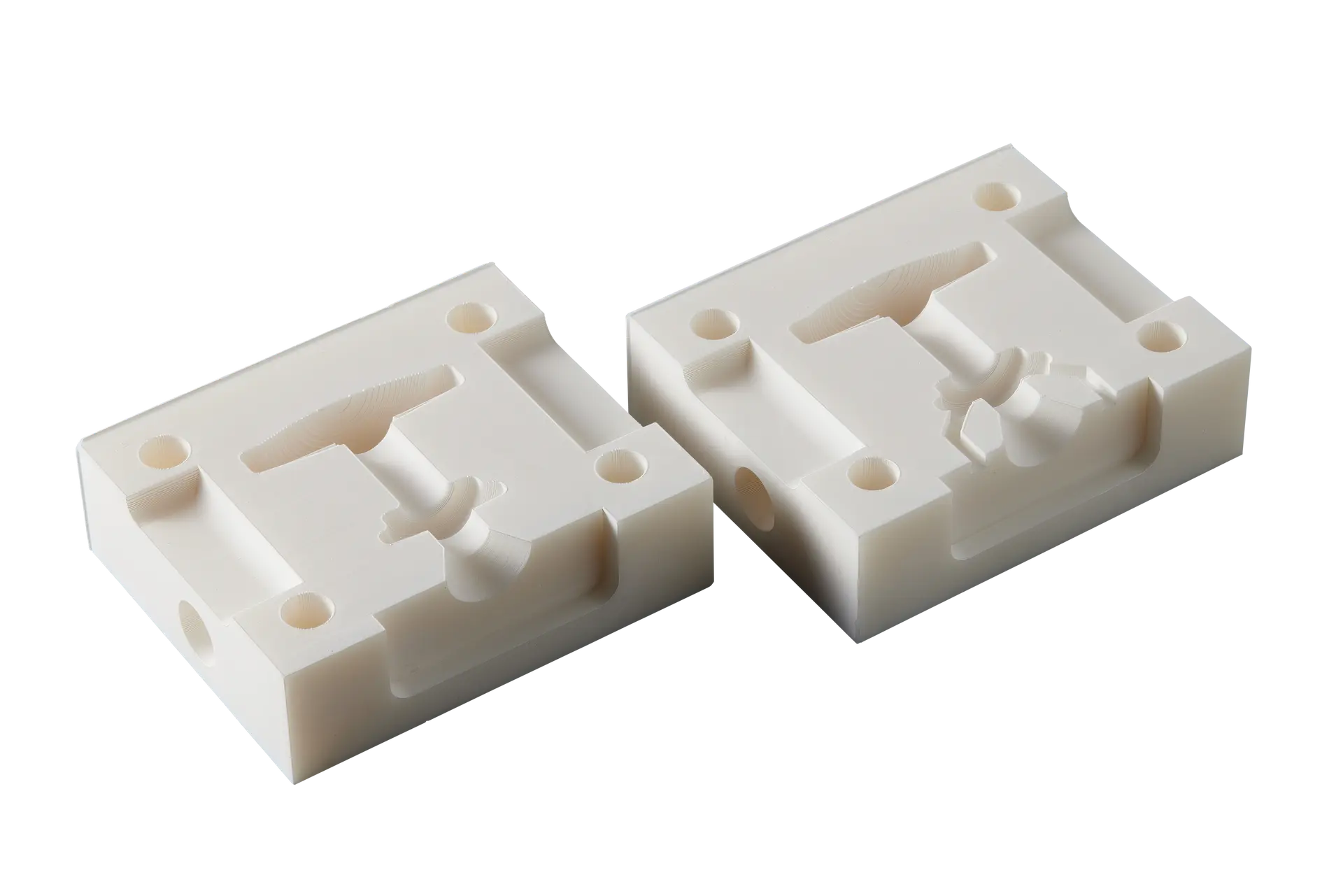

Injection Mold

Manufactturing

Jig

Automotive

Heat Sink & Shield

Consumer Products

Fluidic Device

Fluidics

Gamer Controller

Consumer Products

Surgical Ratchet

Medical

Address any challenge with our top-tier materials or utilize the Open Platform.

Unparalleled reliability. No more dealing with failed prints

- Validated Print Settings

- Intelligent Control Systems

- Long-Lasting Consumables

- Factory Callibration

- Remote Monitoring

So user-friendly that anyone can master printing in just 15 minutes.

The Backlight Unit utilizes 60 LEDs and collimating lenses to produce a uniform area projection of ultra-high-power light. This technology swiftly and accurately cures resin, achieving rapid print speeds while maintaining exceptional print quality and precision across the entire build platform.

The Light Processing Unit 4 (LPU 4) accurately shapes backlight unit light into the form of a printed layer. Working in tandem, the Backlight Unit and LPU 4 facilitate rapid, precise, high-quality printing across the build platform. The LPU 4 boasts durability, resilience against accidental damage, and straightforward replacement.

An exclusive microtextured optical film integrated within the Light Processing Unit facilitates airflow between the resin tank and the unit itself. Positioned atop the unit, this feature substantially minimizes peel forces, allowing for exceptionally fast printing speeds without compromising surface quality, intricate details, precision, or dependability.

Six integrated control systems onboard monitor and regulate printer temperature, resin levels, print forces, and print status with precision. This collective effort guarantees consistent, dependable performance, mitigating potential failures and ensuring uniform results across all printers and prints.

An integrated system efficiently dispenses resin with speed, precision, and minimal waste, facilitating easy material changes. You can print continuously without concerns about resin depletion and switch materials in less than a minute. The Form 4 remains one of the few SLA printers available that provides this capability.

Diverse Applications to Enhance Your Professional Performance

Pre-Production Validation

technology, conducting a five-month vehicle test before finalizing production tooling.

Masking Jigs

Injection Molds

Mass Customized End-Use Parts

Watertight Parts

NOAA’s Atlantic Oceanographic and Meteorological Laboratory (AOML) uses 3D printing to create heavy-duty sampler housings, jigs for experimental sensors and equipment, and customized components for their in-house aquariums.