Form 4 B

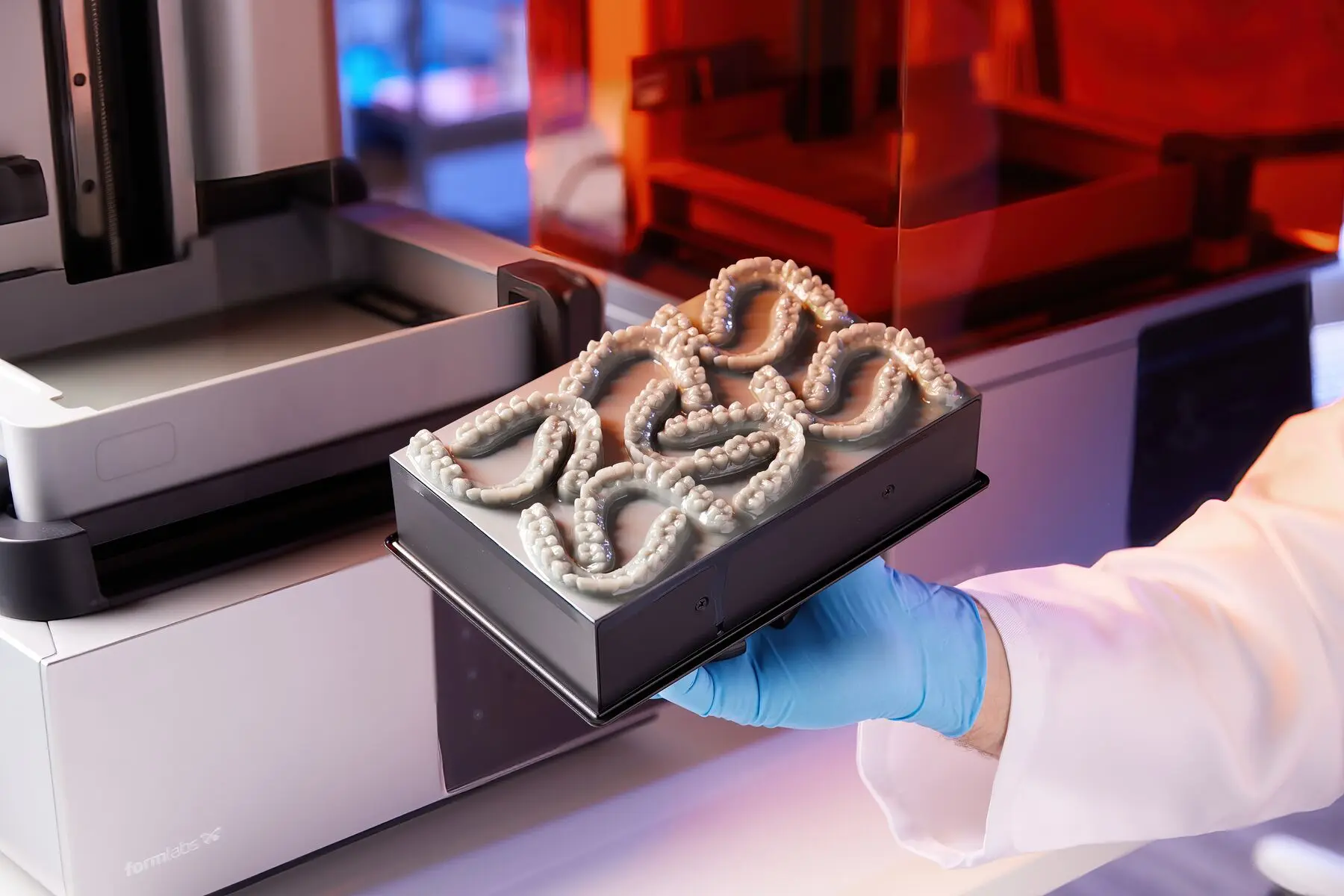

Unrivaled Precision Coupled with Blazing Velocity

Experience unparalleled printing speeds: Create a dental model in just 49 seconds

Clear Aligner Models

Fast Model Resin

Occlusal Splints

Dental LT Comfort

Restorative Models

Precision Model Resin

Surgical Guides

Surgical Guide Resin

All-on-X

Premium Teeth Resin

Crowns and Bridges

Premium Teeth Resin

48 min

8 Surgical Guides

9 min

11 Clear Aligner Models

49 min

8 Splints

18 min

Over 100 Crowns

Unmatched precision that aligns with your dedication to a flawless fit, consistently

Across the build platform

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

±0.15% XY dimensional tolerances so assemblies always fit.

Occlusal Splints

50 μm

Restorative Models

160 μm

Effortlessly produce components for all dental applications.

Reliability that sets the standard. Say goodbye to failed prints.

- Validated Print Settings

- Intelligent Control Systems

- Long-Lasting Consumables

- Factory Callibration

- Remote Monitoring

The Light Processing Unit 4 (LPU 4) accurately shapes light emitted by the Backlight Unit into each printed layer. Working in tandem, they deliver exceptional speed, precision, and print quality across the entire build platform. The LPU 4 is durable, resilient against accidental damage, and designed for easy replacement.

The Light Processing Unit 4 (LPU 4) accurately shapes backlight unit light into the form of a printed layer. Working in tandem, the Backlight Unit and LPU 4 facilitate rapid, precise, high-quality printing across the build platform. The LPU 4 boasts durability, resilience against accidental damage, and straightforward replacement.

Our proprietary microtextured optical film, integrated within the Light Processing Unit and

positioned atop it, facilitates airflow between the resin tank and LPU. This innovation dramatically minimizes peel forces, enabling high-speed printing without compromising surface quality, fine details, accuracy, or reliability.

Six integrated control systems meticulously monitor and regulate temperature, resin levels, print forces, and printing status within your printer. Working together, they guarantee dependable and consistent performance, preempting typical failures to deliver consistent results with every print.

An integrated system that efficiently dispenses resin with speed, precision, and minimal waste, facilitating seamless material switching. Print without concerns about resin depletion and switch materials in less than one minute—a feature that remains exclusive to the Form 4B in the SLA printer market.