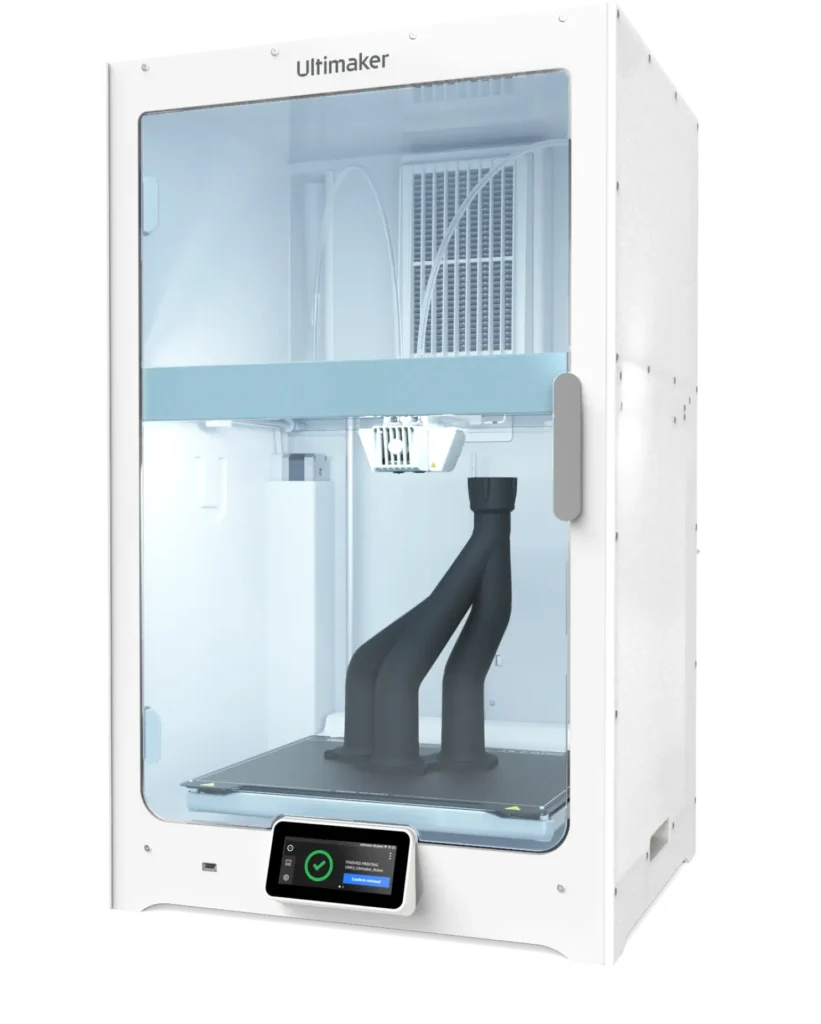

UltiMaker S7

A new level of 3D printing success.

We’ve enhanced everything our customers love about the award-winning UltiMaker S5 in the new S7. Packed with our latest technology, the S7 makes it easier than ever to 3D print high-quality parts.

UltiMaker S7 Pro Bundle

See what sets UltiMaker S7 part

Core benefits

PEI-coated flexible build plate

Integrated Air Manager

More accurate inductive probing

Click and print with 280+ materials

Trusted by the world's top designers and engineers

Printing made easy. Breathing made easy.

Integrated Air Manager

Not only does this enhance peace of mind regarding air quality, but it also improves print quality due to its fully enclosed build chamber and single glass door.

Independently tested

Remove up to

95%

of ultrafine particles from every print.*

* Tested by Fraunhofer WKI. Only including UltiMaker materials.

Show off impressive removal speeds

Flexible build plate

Enhance productivity and minimize the need for glue with the PEI-coated flexible build plate. This innovative, patent-pending design features 25 magnets and 4 pins for precise alignment, allowing for easy removal of parts and saving time when using the S7

PEI-coated

25 magnets

4 alignment pins

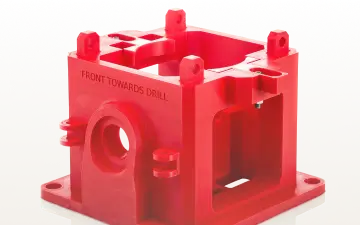

Probing leads to perfection

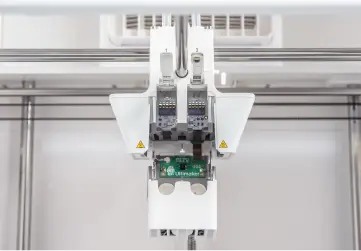

Inductive build plate sensor

A new inductive print head sensor probes the build plate with enhanced accuracy and reduced noise. Automatic tilt compensation eliminates the need for thumbscrew bed calibration. Combined, these features enable you to start a print and walk away with confidence, ensuring a flawless first layer

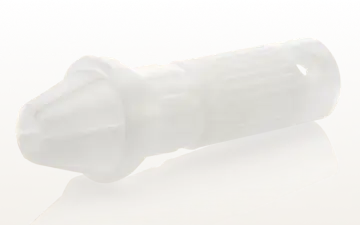

Print with 280+ materials

Unlock the limitless potential of 3D printing applications. These material profiles have been rigorously tested for thousands of hours by manufacturers and users in real-world conditions.

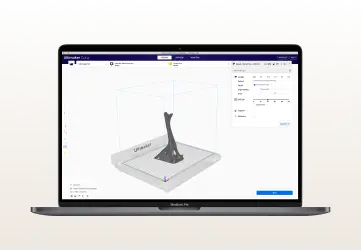

Cura integration

Utilize UltiMaker Cura’s features to enhance your workflow and boost print success, including intent profiles, streamlined remote printing, and more

Backwards file compatibility

The H-bridge gantry and direct drive head facilitate swift dual-material printing. The Factor 4 can achieve temperatures of up to 340°C on its print cores, 70°C in the print chamber, and 120°C on its heated bed.

Anti-flood sensor

The redesigned print head now detects potential flooding sooner and features stronger magnets to ensure the print core door remains securely closed.

Accessories

UltiMaker Metal Expansion Kit

BASF Forward AM Ultrafuse® 17-4 PH (1 kg) BASF Forward AM Ultrafuse® Support Layer (300 g)²

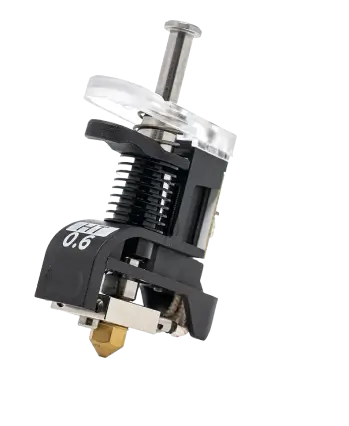

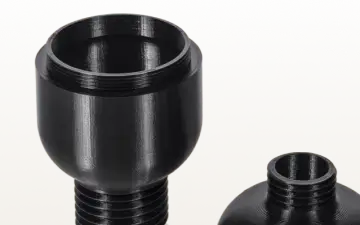

UltiMaker print cores

Choose from material-matched print cores, in multiple nozzle sizes

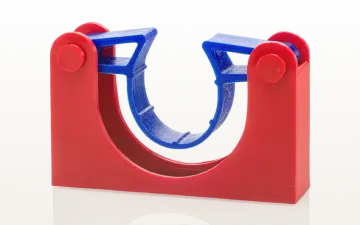

UltiMaker PVA Removal Station

Simple post-processing. Faster parts

The S7 works with 280+ materials including the following:

PLA

Print Core

AA

Hardness

84

Thermal

59°C

Impact strength

4 kJ/m²

Tough PLA

Print Core

AA

Hardness

80 Shore D

Thermal

58°C

Impact strength

9 kJ/m²

PETG

Print Core

AA

Hardness

76 Shore D

Thermal

76°C

Impact strength

8 kJ/m²

ABS

Print Core

1AA

Hardness

76 Shore D

Thermal resistance

87 °C

Impact strength

14 kJ/m²

CPE

Print Core

AA

Hardness

76 Shore D

Thermal

77°C

Impact strength

6 kJ/m²

CPE+

Print Core

AA

Hardness

77 Shore D

Thermal

100°C

Impact strength

37 kJ/m²

Nylon

Print Core

AA

Hardness

81 Shore D

Thermal

89°C

Impact strength

14 kJ/m²

PC

Print Core

AA

Hardness

81 Shore D

Thermal

111°C

Impact strength

12 kJ/m²

TPU 95A

Print Core

AA

Hardness

48 Shore D

Thermal

116°C

Impact strength

24 kJ/m²

PP

Print Core

AA

Hardness

42 Shore D

Thermal

99°C

Impact strength

49 kJ/m²

Specs

Dimensions

- Build volume

- 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

- Assembled dimensions

- W 495 x D 500 x H 1190 mm (W 19.5 x D 19.7 x H 46.9 inches)

- Print technology

- Fused Deposition Modeling (FDM)

- Compatible filament diameter

- 2.85 mm

- Weight

- 29.1 kg (64.2 lbs)

- Maximum power output

- 500 W

Printer properties

- Layer resolution

- 0.25 mm nozzle: 150 - 60 micron 0.4 mm nozzle: 200 - 20 micron 0.6mm nozzle: 300 - 20 micron 0.8 mm nozzle: 600 - 20 micron

- XYZ resolution

- 6.9, 6.9, 2.5 micron

- Feeder type

- Dual-geared feeder, reinforced for composite materials

- Display

- 4.7-inch (11.9 cm) color touchscreen

- Print core replacement

- Swappable print cores

- Print head

- Dual extrusion print head with an auto-nozzle lifting system, swappable print cores, and flood detection.

- Nozzle diameters

- 0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm

Operation parameters

- Filter technology

- Replaceable HEPA H13 filter

- Air extraction rate

- 1 - 50 m³/h (35 m³/h nominal rate for most materials at 23 °C)

- Nozzle temperature

- 180 - 340 °C

- Nozzle heat-up time

- < 2 minutes

- Operating sound

- < 51 dBA

- Build plate leveling

- Advanced active leveling with more accurate inductive sensors

- Build plate

- PEI-coated flexible steel build plate

- Build plate heat-up time

- < 5 minutes (from 20 to 60 °C)

- Operating ambient temperature

- 15 - 32 °C (59 - 90 °F)

- Non-operating temperature

- 0 - 32 °C (32 - 90 °F)

Ecosystem

- Supplied free software

- UltiMaker Cura – print preparation software UltiMaker Digital Factory – printer management software UltiMaker Essentials – enterprise-grade online software tools

- Supported OS

- MacOS, Windows, and Linux

- Plugin integration

- SolidWorks, Siemens NX, Autodesk Inventor

- Supported file types

- UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP

- File transfter

- Wi-Fi (2.4 and 5 GHz), Ethernet, USB

- Certification

- CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, Safe unattended professional use